A look into how and why spiders produce silk, and how scientists have made efforts to synthetically make it and apply it to our lives.

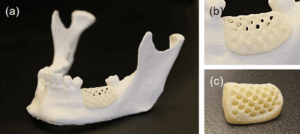

Humans have long been fascinated by spider silk; it has been the subject of African folklore, Greek mythology, and even popular culture through characters like Spider-Man. Spider silk has been prized for its strength and durability for thousands of years. The ancient Greeks used it as a bandage, the Aborigines used it for fishing, and the United States military even used it as a crosshair in optical targeting devices during World War II (1). In modern-day medicine, doctors use spider silk to regenerate skin for burns and tissue repair (2).

Spider silk is approximately one-ten-thousandth the width of a human hair, too small to be seen under an ordinary microscope. Spider webs are only visible to the human eye because each individual strand of a web is made up of thousands of even smaller strands of spider silk (2). It is composed of connected chains of proteins, which give it strength and flexibility (3). The silk starts as a liquid in the spider’s silk gland before hardening into a solid form (3). Once hardened, spinnerets, organs on the spider’s abdomen, extrude the silk fiber, also known as gossamer (3). Spiders use their silk—the strongest fiber on earth—as parachutes, as protection from harsh weather, and as a way to hold food and water, making it vital to their survival (3).

Although spider silk is useful, harvesting it is not commercially viable. It takes hundreds of spiders to make one yard of silk, and because the spiders are cannibalistic, it is not feasible to have them spin silk in close proximity to one another (1). This silk is also very fine and hardens when exposed to air, making it difficult to work with (1). Thus, scientists have begun to study how spiders spin silk in an effort to replicate these methods (1).

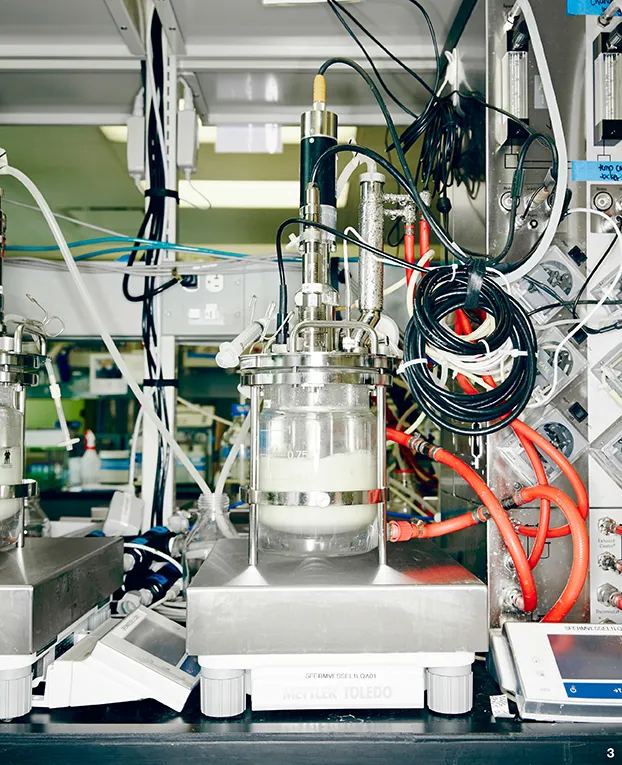

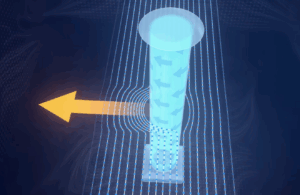

To make synthetic spider silk, scientists first produce and purify the proteins before spinning them into fibers (2). This process is currently flawed: the proteins tend to clump together, making them unspinnable, and the synthetic silk is relatively weak compared to the real thing (2). Thus, scientists are studying the mechanisms of how these spiders spin their silk in an effort to solve the issues with synthetic silk. They discovered that creating a hybrid between two proteins helps the silk hold up better in water and developed a small glass machine (about half as thick as a human hair) to induce the kind of pressure that occurs in a spider’s silk gland (2).

Although the impact of synthetic spider silk is still emerging, its creation could become an alternative way to design and produce lighter devices, biodegradable textiles, and new classes of sustainable materials. What was once a spider’s survival tool may become a new path to human innovation.

Sources:

- University of Bristol. (n.d.). Spider Silk. Centre for Molecular & Microbial Biology, University of Bristol. Retrieved September 27,2025, from https://www.chm.bris.ac.uk/motm/spider/page4.htm

- Dahl, C. (2017, January 9). Scientists have finally figured out how to spin artificial silk the way spiders do. Forbes. Retrieved September 27,2025, from https://www.forbes.com/sites/carmendrahl/2017/01/09/scientists-have-finally-figured-out-how-to-spin-artificial-silk-the-way-spiders-do/

- Branković, M., Živić, F., Grujović, N., Stojadinović, I., Milenković, S., & Kotorčević, N. (2024). Review of spider silk applications in biomedical and tissue engineering. Biomimetics, 9(3), 169. https://doi.org/10.3390/biomimetics9030169. Retrieved from https://pmc.ncbi.nlm.nih.gov/articles/PMC10967872/

Comments are closed.