Various Techniques Are Developing Across the World to Curate Patient-Specific Bone Grafts

Once, a graft meant taking tissue or bone from one part of the body to heal another (1). Now, scientists simply print the replacement. From nanocomposites in Canada to ceramic implants in Denmark to dental grafts in Boston, these innovations are transforming bone and teeth repair. They offer solutions that are more precise, beneficial in the long term, and tailored to the patient.

Traditionally, bone grafts involve taking bone from anywhere in your body, in order to repair broken or diseased bones (2). Another traditional method is bone donation, where recipients are matched with donor bones by size; however these rarely fit properly. There is also very limited donor supply, which makes this an unreliable treatment, and the risk of the body rejecting the donated bone or bone graft is extremely high (3). New and varying technologies solve these problems by customizing the bone grafts. The material used to print the grafts, along with custom sizing makes 3D-printed bone grafts more reliable and patient-specific than traditional techniques.

The University of Waterloo has developed a material to make the 3D printing of bone grafts even more successful. The biopolymer nanocomposite material contains nanoparticles that resemble the minerals in natural bone, providing added strength. Biopolymer nanocomposite is made up of polymers like polysaccharides and proteins and has nanofillers, which are particles added to biopolymers to improve performance (4,5). The researchers’ goal over time is for bone cells to grow into the graft, slowly replacing the biopolymer nanocomposite with new bone tissue. Eventually, the body will naturally break down and remove the remaining biopolymer. Tests conducted by the researchers show that the body better complies with the 3D nanocomposite grafts than with traditional bone grafts. This material eliminates any metal plates that are used in traditional procedures, lowers risk of infection, and tailors the graft to the patient’s needs (3).

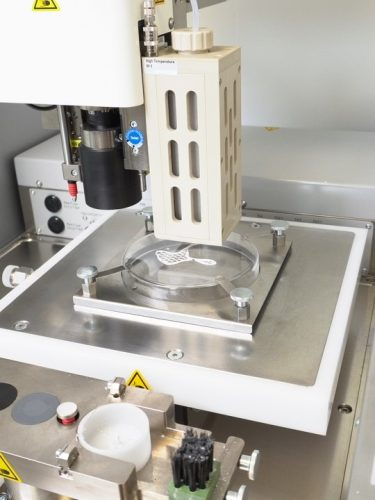

Danish company Ossiform is taking a different route. Rather than develop a new material, they chose to repurpose a material that has been used in the clinical field for over 40 years. Beta-tricalcium phosphate or β-TCP is a resorbable bioceramic material that has been used in orthopedics for spinal fusion, filling bone defects, and orthopedic surgery (6). The human body detects β-TCP as bone and similarly to biopolymer nanocomposite resorbs or replaces the graft with new tissue. Ossiform has created a new technology that provides strength and structure to the material when printing. The bones are printed with large pores to promote cell adhesion and allow for better blood flow throughout the graft (6). Pre-clinical trials show that the Ossiform bone is structurally stable, free of infection signs, encouraging fast growth of new vascularized bone, and successfully resorbing with natural bone (6).

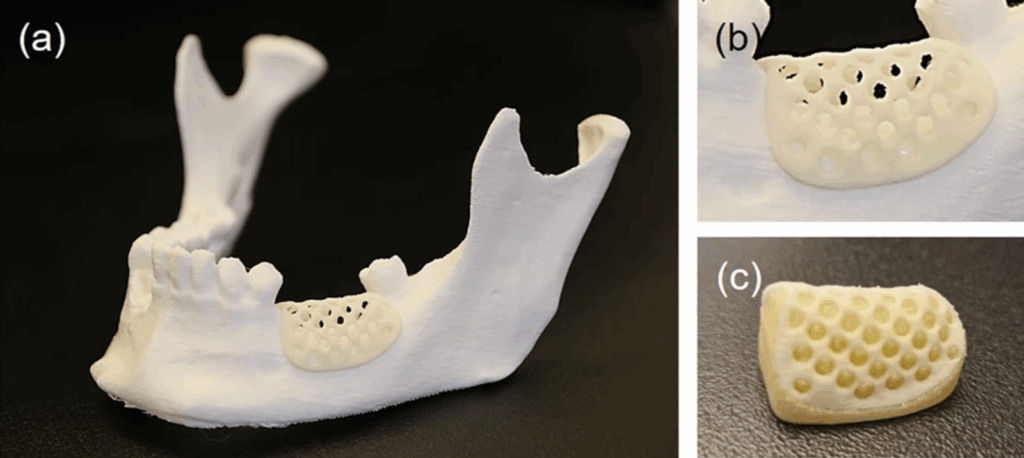

Locally, at Boston’s ADA Forsyth Institute and Brigham and Women’s Hospital, bioengineering efforts are being made to bring 3D bone graft printing to treat bone loss due to periodontitis. Periodontitis is a serious gum disease common in people aged 65 years or older that damages tissue and bone supporting the teeth, often leading to tooth loss (7). Bone grafts traditionally used for periodontitis take six or more months to heal, making this method more trouble than it’s worth, as it also is only somewhat beneficial in the long run. A team at Brigham and Women’s hospital has identified that specialized pro-resolving lipid mediators (SPMs) relieve inflammation. SPMs are found naturally in the human body, but production decreases with age. In order to mitigate inflammation and promote bone regeneration, the 3D printed bone grafts are embedded with SPMs. As with Ossiform and biopolymer nanocomposite, this new bone graft hopes to be replaced by new bone and tissue (7).

The development and rise of 3D printed bone grafts mark a turning point in regenerative medicine and patient-specific treatments. 3D printing bone grafts eliminates concerns that stem from traditional approaches. The ability to personalize the grafts for each patient, control the materials used, and design the implant to work in unison with the body’s regenerative process, allows for innovation and care beyond our time.

Sources

- NCI Dictionary of Cancer Terms. (2025). Cancer.gov. https://www.cancer.gov/publications/dictionaries/cancer-terms/def/graft

- John Hopkins Medicine. (2019). Bone Grafting. Johns Hopkins Medicine Health Library. https://www.hopkinsmedicine.org/health/treatment-tests-and-therapies/bone-grafting

- Building new bones with help from 3D printing | Waterloo News. (2024, August 26). Waterloo News. https://uwaterloo.ca/news/media/building-new-bones-help-3d-printing

- Fouad Egbaria. (2024, April 4). What Are Biopolymers? Dober.com. https://www.dober.com/water-treatment/resources/what-are-biopolymers

- Dolez, P. I. (2015). Nanomaterials Definitions, Classifications, and Applications. Nanoengineering, 3–40. https://doi.org/10.1016/b978-0-444-62747-6.00001-4

- OSSIFORM BONE – Ossiform – WE PRINT BONE. (2025, September 23). Ossiform – WE PRINT BONE. https://ossiform.com/ossiform-bone/

- Rolstad, S. (2025, March 26). New project designs 3D-printed bone graft technology to regenerate tissue – Forsyth. Forsyth. https://forsyth.org/periodontal-bone-graft-thomas-van-dyke/

Images

Comments are closed.